Good News | The excitation motor test bench has been successfully delivered and has received positive feedback from customers

Release time:

2021-06-04

Source:

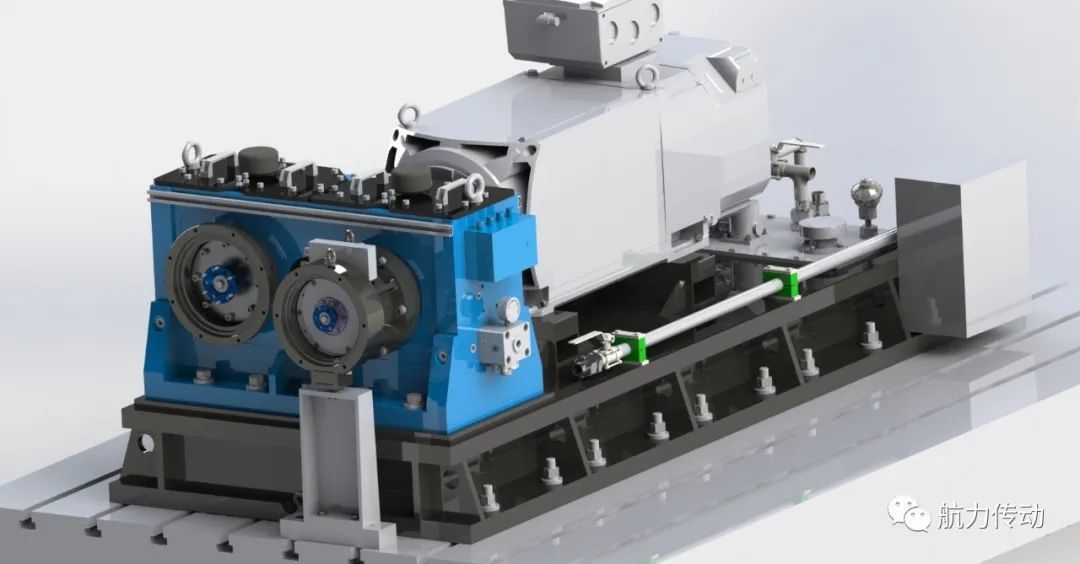

The exciter motor drive test bench (No.: HL200-440) mainly consists of a variable frequency speed regulating motor, a high-speed speed increasing gearbox (single input and double output structure), a mounted torque meter, a base platform, an integrated lubrication system, a measurement and control system, and a monitoring system (including temperature monitoring, vibration monitoring, and speed and torque measurement feedback), realizing the closed-loop load test and test functions of the exciter motor.

The aviation starter motor drive test bench, designed and manufactured by Hangli Transmission, was completed and commissioned on-site in June 2021 at a company of AVIC (Aviation Industry Corporation of China).

The starter motor drive test bench (No.: HL200-440) mainly consists of a variable frequency speed control motor, a high-speed speed increaser gearbox (single input, dual output structure), a mounted torque meter, a base platform, an integrated lubrication system, a measurement and control system, and a monitoring system (including temperature monitoring, vibration monitoring, and speed and torque measurement feedback), realizing the closed-loop loading test and test function of the starter motor electrical power.

Main parameters and characteristics of the test bench:

- Rated power: 200kW

- Rated input speed of motor drive: 4500rpm

- Output speed 1: 17000rpm

- Output speed 2: 31000rpm

- The main structure is a skid-mounted design, with modular integration and compact layout;

- Good system adaptability, applicable to various types of test pieces;

- Easy to use and maintain;

(Picture shows the physical object and 3D modeling design drawing)

Unlike Hangli Transmission's previous independent products, this highly integrated system design allows forrapid deployment at the user's site, saving debugging time.

The Hangli Transmission R&D team completed the development of the test bench. After passing the company's internal professional tests, the equipment was immediately sent to the customer's site. Almost at the same time as the test bench arrived at the customer's site, our installation engineers also arrived on-site to carry out the on-site installation,providing customers with high-quality products and services and ensuring the implementation of turnkey projects.

(Engineers assisting with on-site installation)

"With everyone's cooperation, the whole process went pretty smoothly." Long, who assisted with the installation at the customer's site, said: "We encountered a small problem when installing the cantilever crane. Originally, we wanted to install it on the platform, but later the cantilever crane was changed to a larger one, and the strength of the platform was insufficient. With everyone's cooperation, we built a foundation very efficiently, which did not delay the installation progress."

Currently, the starter motor drive test bench has been successfully delivered, and the on-site operation performance, on-site installation, and After-sale Service have all been highly recognized by the customer.

This test bench will be used in the field of aviation starter motor testing.

Latest News

National Service Hotline:86-731-28827966

Address: Tiantai Jingu Industrial Park, 152 Huanghe South Road, Tianyuan District, Zhuzhou City, Hunan Province

E-mail:18670821903@163.com

Social Media

Mobile website

Copyright @ Hunan Hangli Transmission Machinery Co., Ltd.

The website supports IPv4 and IPv6 bidirectional access