Rotating Machinery Fault Diagnosis

Hangli Transmission, based on its extensive experience in transmission system design and analysis, testing, and service, provides customers with services including machine equipment condition monitoring, rotating machinery fault diagnosis, on-site dynamic balancing, mechanical transmission system installation and removal guidance, mechanical transmission system failure analysis and upgrading and modification, transmission system design and modification, precision alignment, transmission system upgrading and modification, equipment inspection and maintenance packages, and online condition monitoring scheme design and implementation.

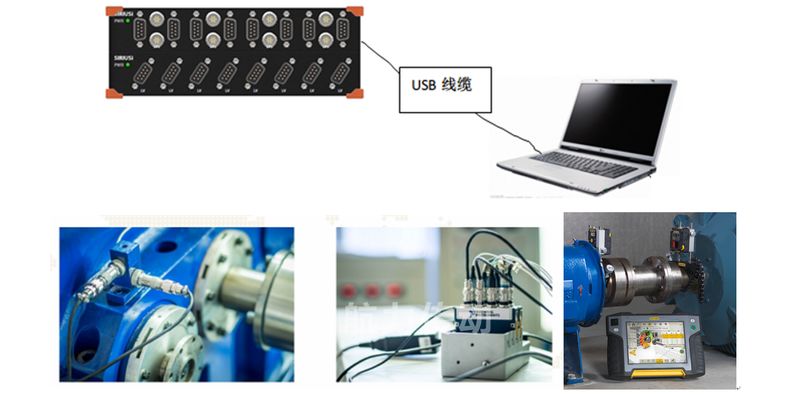

1. Specialized Equipment:

Vibration test sensors and testing equipment, laser alignment instruments, online dynamic balancing machines, etc.

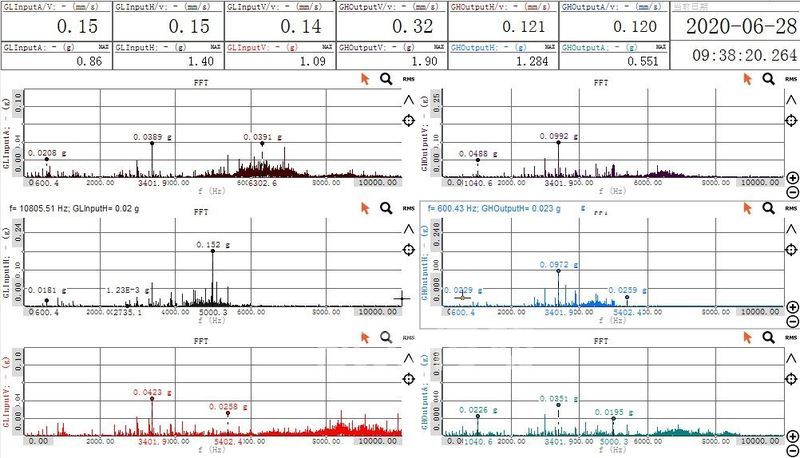

2. Experienced vibration testing and analysis capabilities

3. Experienced company technical service team

• 1 person holds BINDT 2 international vibration analyst qualification;

• 3 senior mechanical system design engineers;

• 1 senior system simulation analysis engineer;

• 1 senior bearing application engineer;

• 1 senior hydraulic design and application engineer

4. Ten aspects of technical services, comprehensively solving your transmission problems

Professional teams and equipment provide users with professional testing and services, and can provide testing and services for the following specific parameters

• Measurement of the free mode and natural frequency under specific support of the shaft

• Measurement of the natural frequency of the bracket

• Measurement of the natural frequency of the gearbox

• Modification of vibration analysis model parameters (bearing stiffness, casing stiffness, damping, etc.)

• Quality inspection of complex rotor assemblies such as compressors

• Comparison of characteristics before and after repair of complex rotors such as compressors

• Baseline calibration of equipment condition monitoring and alarm shutdown

• Equipment fault location and diagnosis

• Measurement of vibration response transfer function

• Measurement of system shaft misalignment

5. Main Achievements

Factory In-plant Tests

• Gearbox factory natural frequency sweep and condition monitoring

• Flywheel box factory natural frequency sweep and condition monitoring

• Center support factory natural frequency sweep and condition monitoring

• Motor factory natural frequency sweep and condition monitoring

On-site Services

(1) Fault location and diagnosis of Xiangdian Motor test bench

(2) Sifang eddy current brake test bench natural frequency sweep and analysis model parameter modification

(3) Condition monitoring and fault diagnosis of Anyang Shenlong rolling mill gearbox

(4) System condition monitoring and fault diagnosis of 5701 factory XX test bench

(5) Dongfang Steam Turbine XX test bench condition monitoring and fault diagnosis

(6) Vibration monitoring and analysis of F18 test system

(7) Vibration analysis of 70 Institute cryogenic test bench

(8) Fault location and diagnosis of Kohler performance test bench

National Service Hotline:86-731-28827966

Address: Tiantai Jingu Industrial Park, 152 Huanghe South Road, Tianyuan District, Zhuzhou City, Hunan Province

E-mail:18670821903@163.com

Social Media

Mobile website

Copyright @ Hunan Hangli Transmission Machinery Co., Ltd.

The website supports IPv4 and IPv6 bidirectional access