The inertial flywheel assembly for the tank brake system test bench has been successfully delivered to the customer

Release time:

2023-07-06

Source:

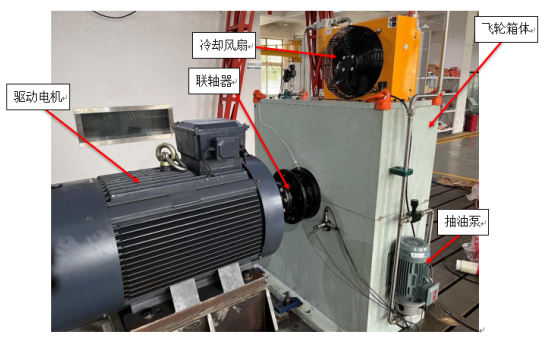

In April 2023, the inertial flywheel assembly (HLF200-3000) for the tank brake system test bench was successfully delivered to the customer site and received unanimous recognition. As a manufacturer of inertial flywheels, Hangli Transmission is already very experienced in the research and development of large inertial flywheels. It is understood that this inertial flywheel assembly will be used in a brake test bench flywheel project for a military unit.

In April 2023, the HLF200-3000 inertial flywheel assembly for the tank brake system test bench was successfully delivered to the customer site and received unanimous approval. Hangli Transmission, as the manufacturer of inertial flywheels, is already very experienced in the research and development of large inertial flywheels. It is understood that this inertial flywheel assembly will be used in a brake test bench flywheel project for a military unit.

In addition to the HLF200-3000 inertial flywheel assembly, there are also supporting facilities:

1. Variable frequency speed control motor

Rated power: 200kW

Speed: 0~3000r/min

Speed control accuracy: ±1.0%F.S (F.S represents full scale)

2. Test bench

Including installation platform, double-membrane coupling, various monitoring components and secondary instruments, cables, etc.

3. Temperature acquisition system: Beckhoff PLC and temperature module from Germany, K-type thermocouple temperature sensor;

4. Vibration testing equipment: Dewei Chuang SIRIUS-8xACC, accelerometer, sensitivity 20mv/g.

The customer commissioned us to design, manufacture and test the HLF200-3000. Before leaving the factory, a factory operation test was conducted to assess the flywheel design and assembly quality, test the bearing temperature and housing vibration, assess the oil leakage and seepage of the seals, and assess the performance of the supporting accessories. The test requirements are: bearing temperature: <80℃ (a total of 2 temperature measurement points); vibration value on the housing: steady-state vibration RMS value ≤4.5mm/s

During the factory test, the ambient temperature was 10℃. When the speed reached 3000rpm, the highest bearing temperature was 26.3℃, and the bearing temperature rise was 16.3℃; the highest allowable bearing temperature is below 80℃, meeting the factory requirements; the flywheel housing vibration RMS value at 2700rpm was 2.04mm/s (the maximum during the entire operation), less than the limit value of 4.5mm/s, meeting the factory requirements. No oil leakage or seepage was found, and the vibration characteristics of the flywheel input and output ends were good. Through continuous operation of the test bench, the performance was stable, and all indicators met the design and customer requirements; after the test, the flywheel status was checked on site, there were no oil leakage or seepage points, and no loose connecting fasteners were found. The flywheel met the design requirements and was ready for shipment.

Hangli Transmission is always committed to the design and manufacturing of transmission mechanical equipment, especially high-speed flywheels and aviation inertial flywheels, with rich experience. Adhering to the principles of "Careful design, reliable quality, accurate delivery, and attentive service," we are committed to applying aviation transmission technology to various fields of mechanical transmission manufacturing. With advanced technology, reliable products, and customer-centric service, we strive to become a strong and competitive partner and strive to be the "leader" of Hunan flywheel manufacturers!

Latest News

National Service Hotline:86-731-28827966

Address: Tiantai Jingu Industrial Park, 152 Huanghe South Road, Tianyuan District, Zhuzhou City, Hunan Province

E-mail:18670821903@163.com

Social Media

Mobile website

Copyright @ Hunan Hangli Transmission Machinery Co., Ltd.

The website supports IPv4 and IPv6 bidirectional access