Localization of gearboxes and transmission systems for vertical rotor testers

With the development of domestic aero-engines and high-speed equipment, many domestic engine research institutes, engine manufacturers, universities, and high-speed equipment manufacturers have introduced a large number of imported vertical overspeed testers, including those from Schenck, TDI, and BSI. However, with changes in the international situation, soaring tariffs and trade frictions, and geopolitical risks strengthening the need for self-reliance, the localization and maintenance of key equipment for vertical overspeed test stands have become increasingly important for major manufacturers. In particular, many devices have been in use for nearly a decade, and the repair, replacement, and procurement costs and cycles of key systems such as gearboxes, transmission systems, damping systems, and spare parts have significantly limited equipment efficiency and costs. For example, a US XXX device purchased nearly ten years ago experienced problems including abnormal noise in the system gears, large operating vibrations, increased bearing detection temperatures, spline wear, and magnetic seal failure, rendering it unusable. Spare parts have long lead times and are expensive; it is understood that replacing imported spare parts for a single burst test costs hundreds of thousands of RMB.

This article focuses on the localization project of key components—gearbox and transmission system—of the US XXX vertical overspeed tester implemented by Hunan Hangli Transmission Co., Ltd. at a domestic engine research institute.

Main parameters of the vertical overspeed tester:

Main parameters of the vertical overspeed tester:

• Rated power of the drive end: 265kW • Maximum output speed: 25000rpm

• Maximum torque: 1250Nm • Transmission system load weight: 800kg

• Diameter of the test piece wheel: 2000mm • Height of the test piece wheel: 1500mm

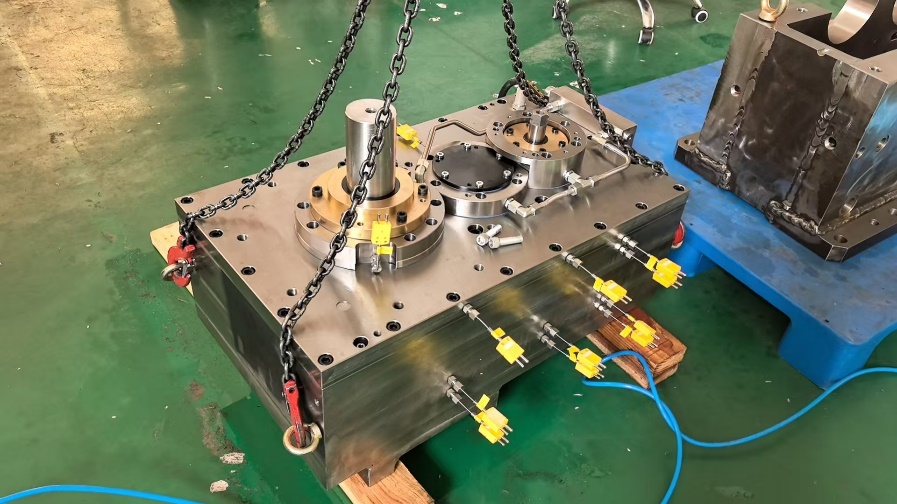

This project mainly focuses on the localization of the tester's gearbox and transmission system. The integrated gearbox and transmission system are shown in the figure on the right, installed at the customer's site.

Gearbox Introduction:

• The gearbox is designed to match the interface requirements of existing imported testers;

• Gearbox structure: Two-stage parallel shaft gear transmission, single input and single output structure;

• Transmission ratio: Gearbox transmission ratio: 5.236

• All bearings use mature, readily available products; major bearing models can be procured from two brands;

• Gear accuracy level 5;

Figure 2: Actual photo of the gearbox after completion of factory testing

Transmission System Introduction:

• The transmission system is designed to match the interface requirements of existing imported testers;

• The transmission system mainly includes: support device, spare parts replacement mechanism, sealing and damping mechanism.

• Speed: 25000rpm

• Maximum load-bearing weight of the test piece: 800kg

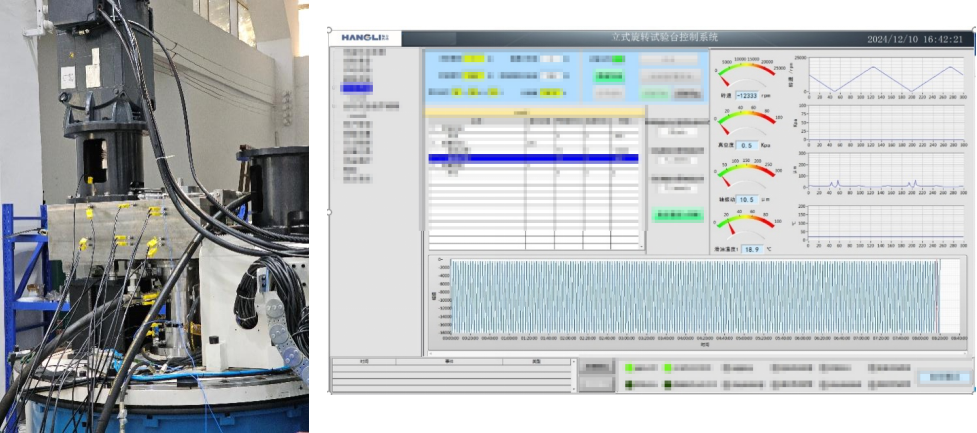

After integration, the gearbox and damping system were tested on our company's self-developed vertical overspeed tester (HLSTS100-maximum speed 60000rpm). Test conditions: vertical installation, vacuum environment, with simulated wheel; after 500 cycles of testing on our company's test bench, all performance indicators met the design requirements, and received customer recognition and praise.

Figure 3: Factory tester factory test - 500 cycles

After completing the factory test, our company performs rust prevention treatment and packaging before shipping. Engineers are dispatched to the customer's site for on-site installation and commissioning, and cooperate with the user to solve other on-site problems, realizing a turnkey project. The project delivery has been highly recognized and praised by the user: "We no longer have to worry about foreign blockades and exorbitant prices."

Figure 4: Final installation and commissioning at the customer's site

Welcome to inquire about vertical rotor testers and the localization of key gearboxes, transmission systems, and damping systems for vertical rotor testers. Contact us for procurement and cooperation at 0731-28827966.

Previous Page

Next Page

National Service Hotline:86-731-28827966

Address: Tiantai Jingu Industrial Park, 152 Huanghe South Road, Tianyuan District, Zhuzhou City, Hunan Province

E-mail:18670821903@163.com

Social Media

Mobile website

Copyright @ Hunan Hangli Transmission Machinery Co., Ltd.

The website supports IPv4 and IPv6 bidirectional access