Products

PRODUCT

Tank vehicle pump motor test bench

Classification:

Non-standard test bench

Hotline:

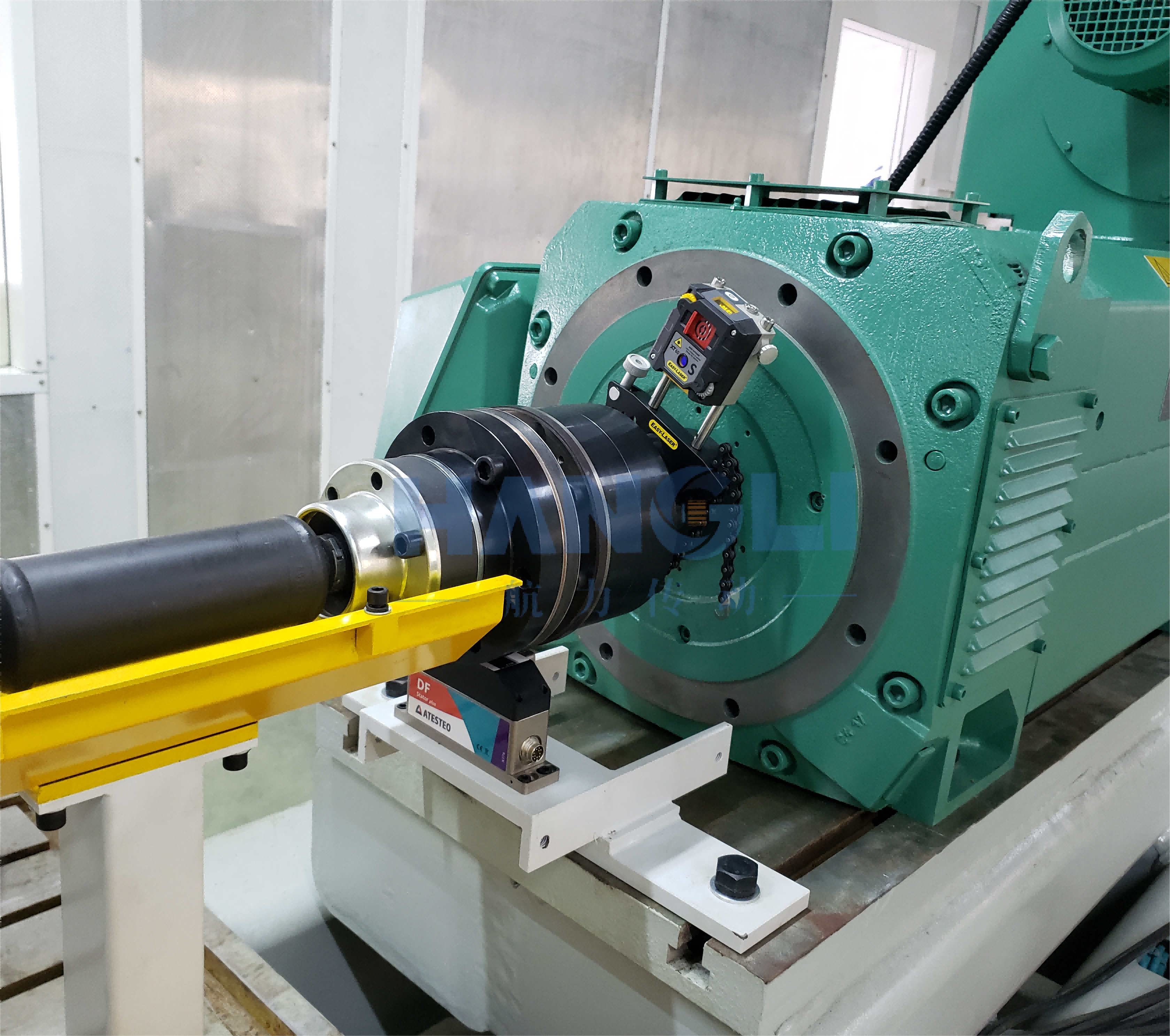

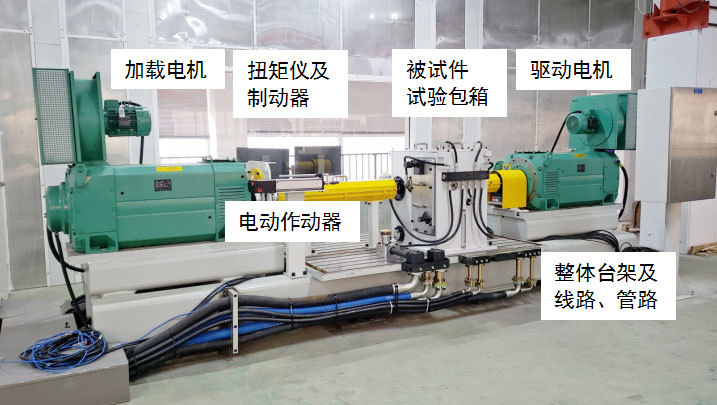

The tank vehicle pump motor test bench is a test bench for conducting performance tests, durability tests, factory tests, etc., on pump motor components. The test bench structure is in the form of an electrically powered enclosure. It is driven by a drive motor, and the load motor is used for loading and power recovery. The test piece is installed in a non-standard custom test package box.

The test piece is equipped with an independent hydraulic power station, which controls the pressure and flow of the test piece's oil circuit through a precision servo valve, and automatically controls the valve through an electro-actuator.

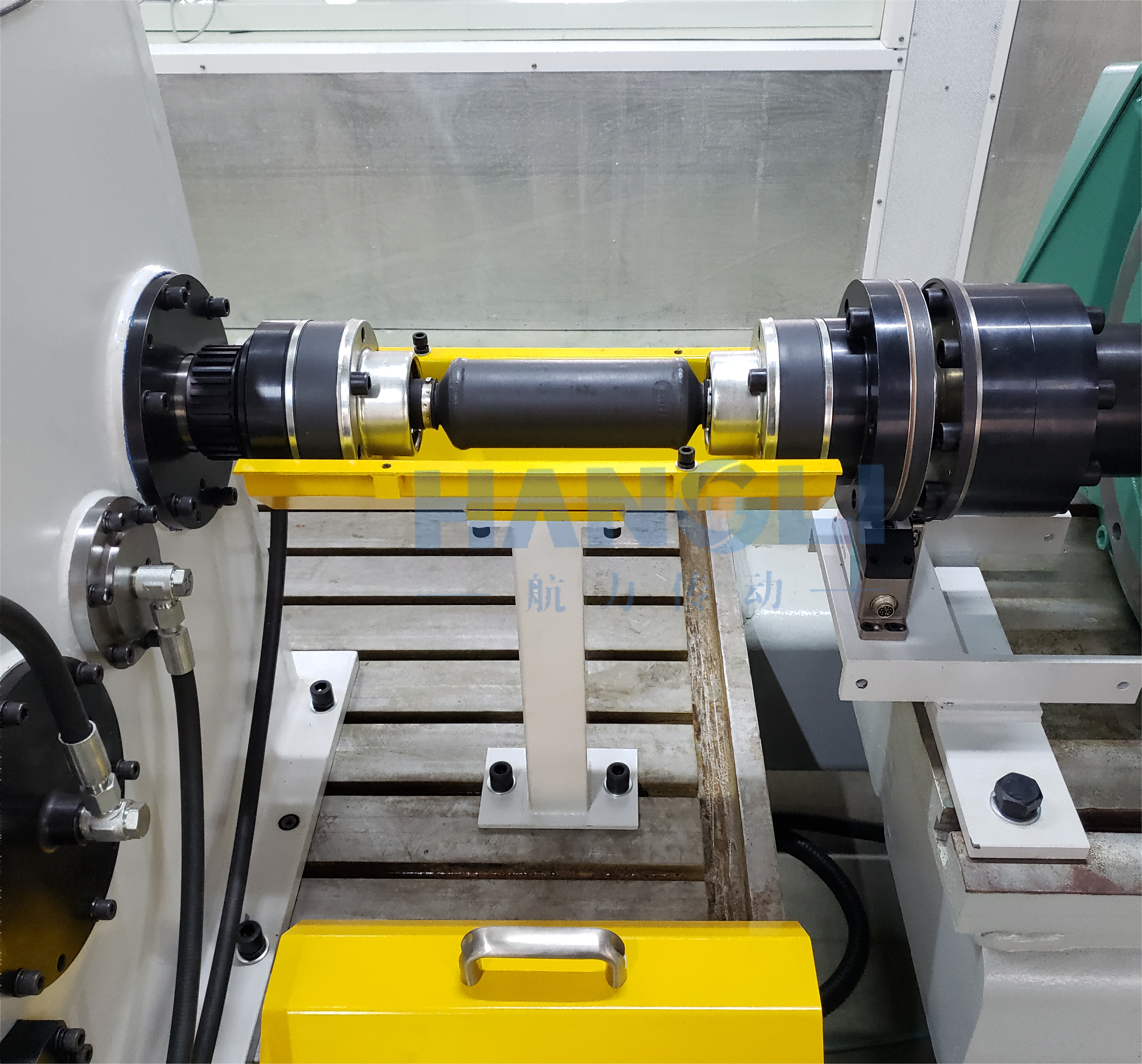

The input and output of the test package box are connected to the drive and load motors through ball cage constant velocity universal joints. Different test pieces are installed in different test package boxes. When replacing them on the test stand, no re-centering is required. The positioning mechanism can automatically center, greatly reducing the installation time required for replacing the test piece during factory testing.

- Drive/Load Motor: 250kW

- Drive Speed: 4500rpm

- Hydraulic Station Pressure:

- Hydraulic Station Flow Rate:

- 450kW Electrically Powered Enclosed Test Bench

- Maximum speed 5000rpm, maximum torque 2000Nm.

- It can test 3 Models of steering pump motors. With a hydraulic control system, the hydraulic system is 250L/min, and the maximum pressure is 500bar (inside the pump and motor).

Key words:

High precision transmission products

Previous Page

Previous Page

Recommend Products

The business includes aviation transmission products, high-speed gear transmission products, high-speed inertial flywheel, torque loader, aero-engine component test bench, and other fields of test bench development and sales, transmission equipment testing, fault diagnosis and maintenance services.

Why choose us

Assembly and test verification capability

It has a test assembly plant of 3000m ², equipped with high-precision lathes, grinders, milling machines and other equipment. Adhere to zero defects in products, attach importance to the construction of quality system, and build a high-speed transmission comprehensive test bench. The maximum test power of the test bench is 200kW, the maximum test speed is 60000r/min, and the maximum oil supply capacity is 200L/min. Equipped with DEWETRON vibration monitoring system, Easy-laser laser laser alignment instrument and Hikvision closed-circuit monitoring system, it can meet the comprehensive operation test of gear box, inertial flywheel unit, air compressor, clutch and other products, and can provide fault analysis service of rotating parts.

Complete system design and analysis capabilities

Our company has complete mechanical transmission design and analysis capabilities, including the following: • Overall mechanical system design and R & D capability • Rotor dynamics system analysis • Shell Finite Element Analysis • Coupling design and application technology • Lubrication system design and • Aerodynamic analysis • Gear transmission system design and analysis • Bearing analysis and application technology: sliding bearings/rolling bearings • Ability to design and analyze shaft parts • Connection design analysis: bolt/pin/spline/flat key/interference connection • Seal design and analysis • Vibration testing and analysis

Design fast response capability

It has complete staffing for mechanical transmission design and electrical drag measurement and control technology, covering all aspects of system overall design, zero/component structure design, system analysis and calculation, testing, assembly and testing verification, and can quickly grasp and understand customer needs. At the same time, combined with the company's experience in large-scale mechanical transmission projects, it can quickly provide customers with complete customized mechanical system solutions.

Excellent customer service experience

We continue to provide customers with systematic mechanical transmission solutions, such a business model requires the company and customers in-depth communication and coordination process, familiar with customer products, familiar with customer needs and expectations, from the customer's point of view, in order to maximize customer value as the core.

Technology and Services

Technology Center

Hunan Air Force Transmission Technology Center was established by the former AVIC Aviation R & D team, focusing on the field of mechanical transmission. The technology center covers six technical directions: overall system design, structural design of parts/components, system analysis and calculation, testing, assembly and test verification.

Testing and Services

In order to verify the design of new products and ensure the quality of product development, our company has invested in the construction of a high-speed transmission comprehensive test bench. The motor power of the test bench is 250kW (expandable to 500kW); Through the gearbox speed increase, the maximum test speed can reach 60000r/min; With torque loading capacity, the loader has a maximum working speed of 8000rpm and a maximum loading torque of 600Nm; Servo electric cylinder; Can supply oil to four equipment at the same time, with a single maximum oil supply capacity of 200L/min. The test bench is equipped with Austrian DEWETRON vibration test and analysis system, EasyLaser laser alignment, Hikvision closed-circuit monitoring system, analog real-time monitoring system for temperature, pressure, flow, etc., and belt drive dynamic balancing machine.

fault diagnosis of rotating machinery

Based on extensive experience in drivetrain design and analysis, testing and service, provide customers with services such as condition monitoring of machinery and equipment, fault diagnosis of rotating machinery, on-site dynamic balance, installation and disassembly guidance of mechanical transmission system, failure analysis and upgrading of mechanical transmission system, design and upgrading of transmission system, precision centering, upgrading of transmission system, spot inspection and maintenance packaging of equipment, design and implementation of online condition monitoring scheme, etc.

Regenerative Manufacturing Services

The high-speed gearbox of a certain type of test bench has the problems of large vibration, spline wear, bearing temperature rise and oil leakage. After several years of use, the vibration is seriously excessive and can no longer be tested. Customers seek solutions. After communicating with customers, the relevant technical personnel of our company will introduce the remanufacturing concept of transmission equipment to customers.

Online Message

National Service Hotline:86-731-28827966

Address: Tiantai Jingu Industrial Park, 152 Huanghe South Road, Tianyuan District, Zhuzhou City, Hunan Province

E-mail:18670821903@163.com

Social Media

Mobile website

Copyright @ Hunan Hangli Transmission Machinery Co., Ltd.

The website supports IPv4 and IPv6 bidirectional access